Radiation sources in digital radiography: how they affect image quality?

In industrial digital radiography (DR), achieving high-quality images is essential for detecting defects and ensuring structural integrity. The choice of radiation source plays an important role in determining contrast, sharpness, penetration and overall radiograph clarity. Different sources have distinct characteristics that impact image quality based on energy output, beam consistency and scatter.

Let’s take a closer look at the most commonly used radiation sources in RT and how they influence imaging performance.

Constant-potential (CP) X-ray generators – the best choice for digital radiography

Constant-potential X-ray generators provide a steady, high-energy output without fluctuations, ensuring uniform beam intensity throughout the exposure. This results in:

Sharper images with excellent contrast;

Minimal noise compared to other X-ray sources;

Superior sensitivity for fine defect detection;

Fastest time of exposure, especially for small radiation thicknesses (a matter of seconds).

Because of their stability and consistent radiation output, CP X-ray sources are widely used in aerospace, precision weld inspection and high-resolution industrial imaging applications where image quality is a top priority. They also allow the selection of not only the voltage but also the current, making it an ideal solution for digital radiography inspection of objects of various thicknesses from just a couple of millimeters of aluminum to up to 70-80 mm of steel. However, they are quite costly and require a steady power supply, which results in their limited application, especially in the field.

Half-sine X-ray generators – lower contrast and more noise

Half-sine wave X-ray generators produce an output with fluctuations in intensity, leading to:

More noise in the image due to inconsistent beam energy;

Reduced contrast, making small defect detection harder;

Higher dose requirements compared to CP sources for equivalent image quality;

Longer and more difficult selection of proper exposure parameters due to the unavailability of current selection.

Being a much cheaper option than constant-potential ones, these sources remain popular in many countries. Nevertheless, currently, they tend to lose some share and are being slowly replaced by CP generators due to their constraints in image clarity and limited durability. Also, one of the common problems for the use of this type of source with digital radiography complexes is a so-called "stripes" effect, which, however, can be avoided in most cases by professional operators.

Pulsed X-ray generators – portable, but limited application

Pulsed X-ray systems emit short bursts (pulses) of high-intensity radiation. While this reduces motion blur in field applications, they come with certain limitations:

Higher-intensity pulses improve penetration, but the varying dose may affect image consistency;

Lower contrast and more noise than with the CP sources;

The impossibility of adjusting the voltage leads to the longer time of optimal parameters selection and exposition;

Finite resource of application, changing of output spectrum over time.

Pulsed sources are most often used in applications where portability is key, such as military and security areas: Explosive Ordnance Disposal (EOD), Improvised Explosive Device Disposal (IEDD) and Public Safety Bomb Disposal (PSBD). Yet, a very tight range of available settings and difficulties related to the pulsed nature of signal emission make it a bad choice for industrial high-quality radiography.

Iridium-192 (Ir-192) – versatile, but with lower contrast

Iridium-192 is a widely used Gamma-ray source due to its high-energy output, portability and most attractive price. However, it has some specifics when using it with digital radiography:

More scatter radiation, leading to reduced image sharpness;

Lower contrast compared to X-ray sources;

Difficulties with achieving high sensitivity with objects of small radiation thickness;

Longer exposure time.

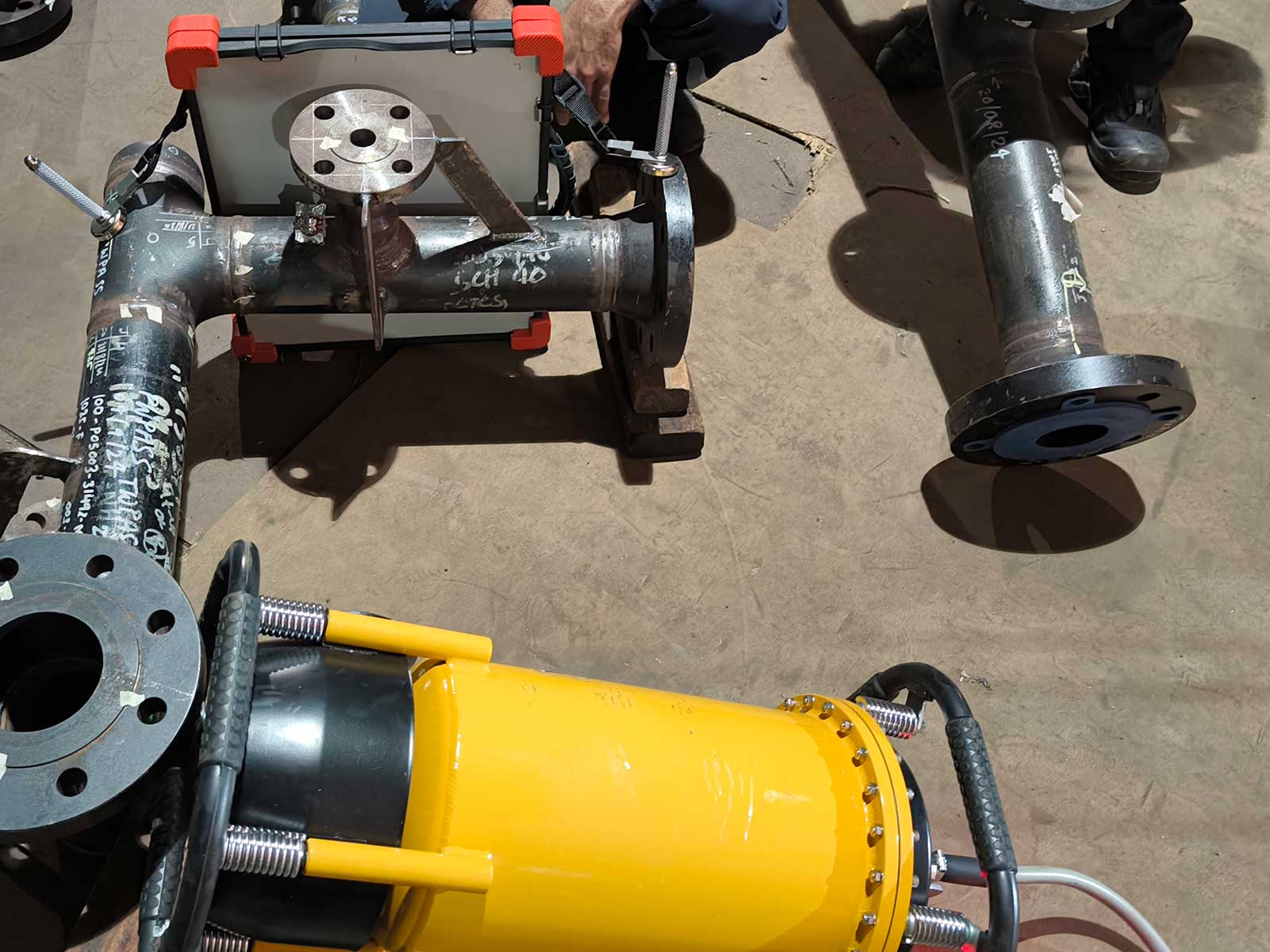

Despite these cons, Ir-192 remains a preferred choice for pipe welds and field inspections where X-ray equipment is impractical. It is also a perfect option for the remaining wall thickness estimation (profilometry) and castings radiography inspection thanks to the enhanced penetration strength. When using Gamma sources, one should always remember that the exposure time will strongly depend on the remaining isotope activity.

Selenium-75 (Se-75) – better contrast for thin materials

Selenium-75 operates at a lower energy level than Ir-192, resulting in:

Improved contrast for thin-wall materials (up to ~20 mm steel);

Lower scatter radiation, enhancing image clarity;

Best for SCAR (Small Controlled Area Radiography) application;

Reduced penetration thickness.

Se-75 is commonly used for thin-walled pressure vessels, aerospace components and fine-detail inspections where contrast is more critical than penetration depth. A higher price than Ir-192 is partially compensated by a longer half-life period.

Cobalt-60 (Co-60) – high penetration but low image quality

Cobalt-60 is a powerful Gamma-ray source used for thick-section industrial inspections. Its key characteristics include:

The biggest penetration depth;

Significant scatter radiation and lower contrast;

Higher noise level compared to Ir-192 and Se-75;

The strictest use and storage precautions to be followed.

Because of its lower image quality, Co-60 is primarily used in heavy industrial applications, such as nuclear reactor components and large castings, where alternative sources may not be effective enough. The use for thin-wall objects is impossible. It is strongly advised to keep the detector safe from direct exposure from this source by inspection object or shielding.

Comparing radiation sources for image quality

Radiation source | Penetration | Contrast | Noise | Best use cases |

|---|---|---|---|---|

CP X-ray | Medium | Very high | Low | High-quality imaging, aerospace, precision welds |

Half-sine X-ray | Medium | High | Medium | Projects with a limited budget |

Pulsed X-ray | Medium | High | Medium | Military and security areas (EOD) |

Ir-192 | High | Medium | High | Wall thickness estimation (profilometry) |

Se-75 | Low | High | Medium | Thin-wall materials |

Co-60 | Very high | Low | Very high | Thick-wall components |

Conclusion

Selecting the right radiation source for digital radiography depends on the project task, image quality requirements, object parameters, inspection conditions and, of course, the budget available. Understanding the main differences described above helps ensure the proper use of the various sources with DR, making inspections more accurate and reliable.

In the end, it is important to mention that yet the source is important, a skilled expert can reach the required image sensitivity in most cases with any of it while using a proper digital radiography system and the right software. Therefore, we always advice paying much attention to the proper training and gaining working experience. And we are here to share ours!